Dong Fu Yuan Fluid Equipment Co., Ltd. is a professional manufacturer specializing in the production of hygienic stainless steel valves, pipe fittings, pumps and other fluid equipment. Its products are widely used in the production line and pipe systems in sanitary industries like dairy, food and beverage, brewery, biological and pharmaceutical engineering, fine chemical, cosmetics and so on.

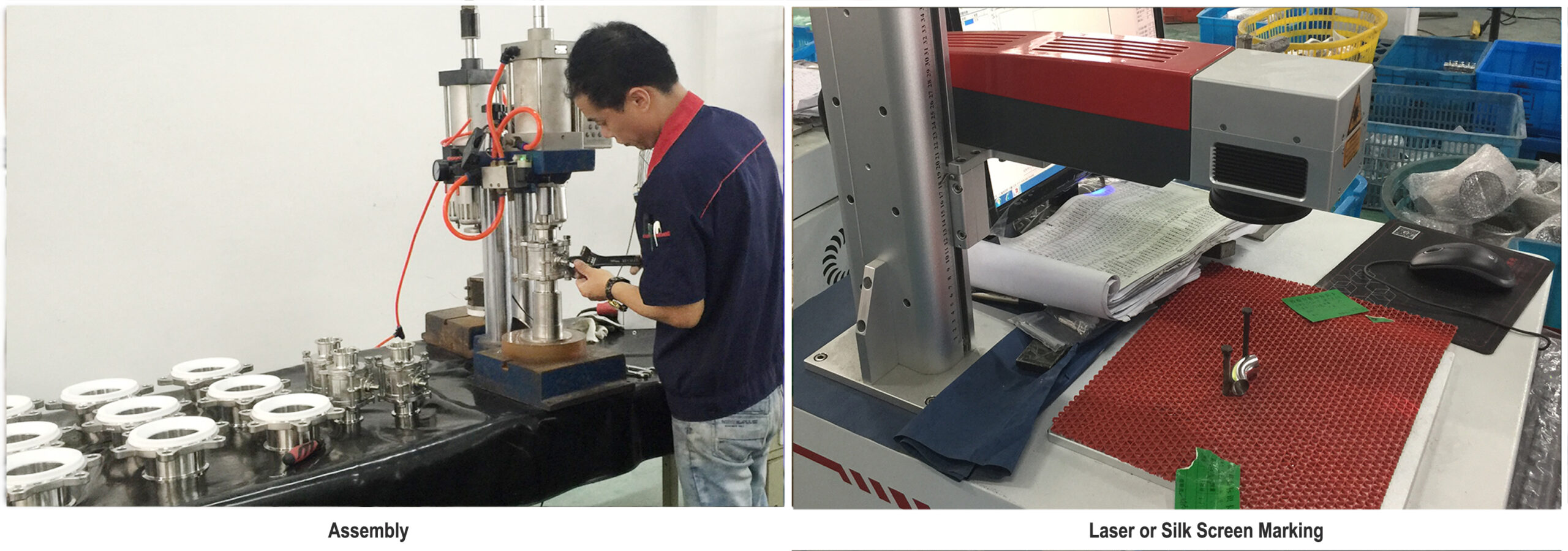

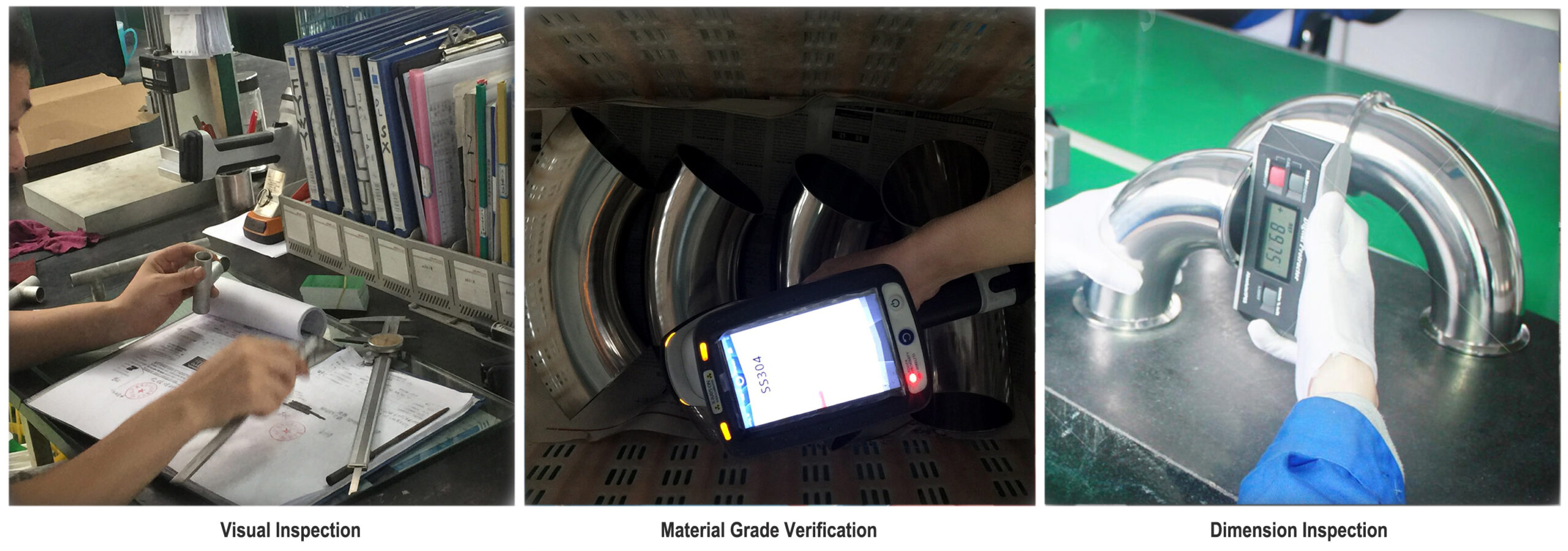

We have the widest range of sanitary stainless steel products covering sanitary valves, stainless steel tubes, pipe fittings, unions, ferrules, flanges, and also OEM and customized stainless steel products. All of them are manufactured strictly according to ISO, DIN, IDF, 3A, SMS and other international industrial standards. We devote ourselves in combining strict manufacturing standards and quality control system together, and carrying out quality control monitoring during the whole production process.

Since established, we’ve already been approved by all outstanding customers due to our excellent service and best quality. We will keep optimizing product quality with its management system and sincere service, so that “ Dong Fu Yuan fluid equipment” becomes a strong partner satisfying customers both at home and abroad.

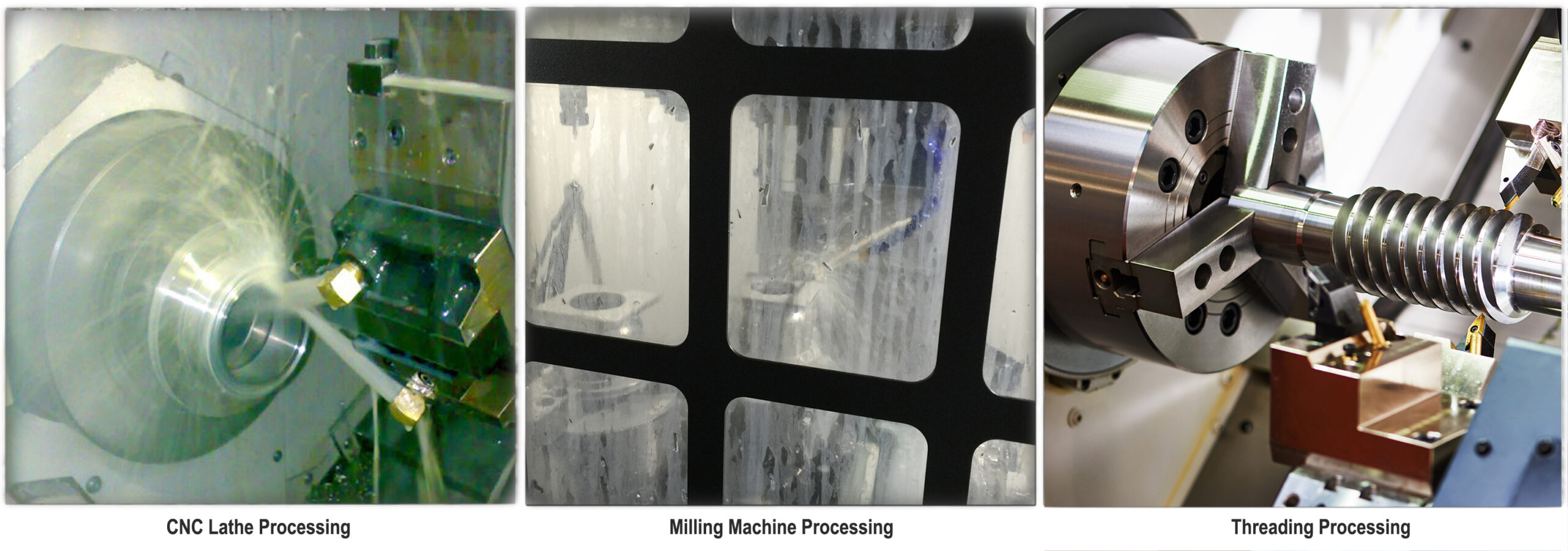

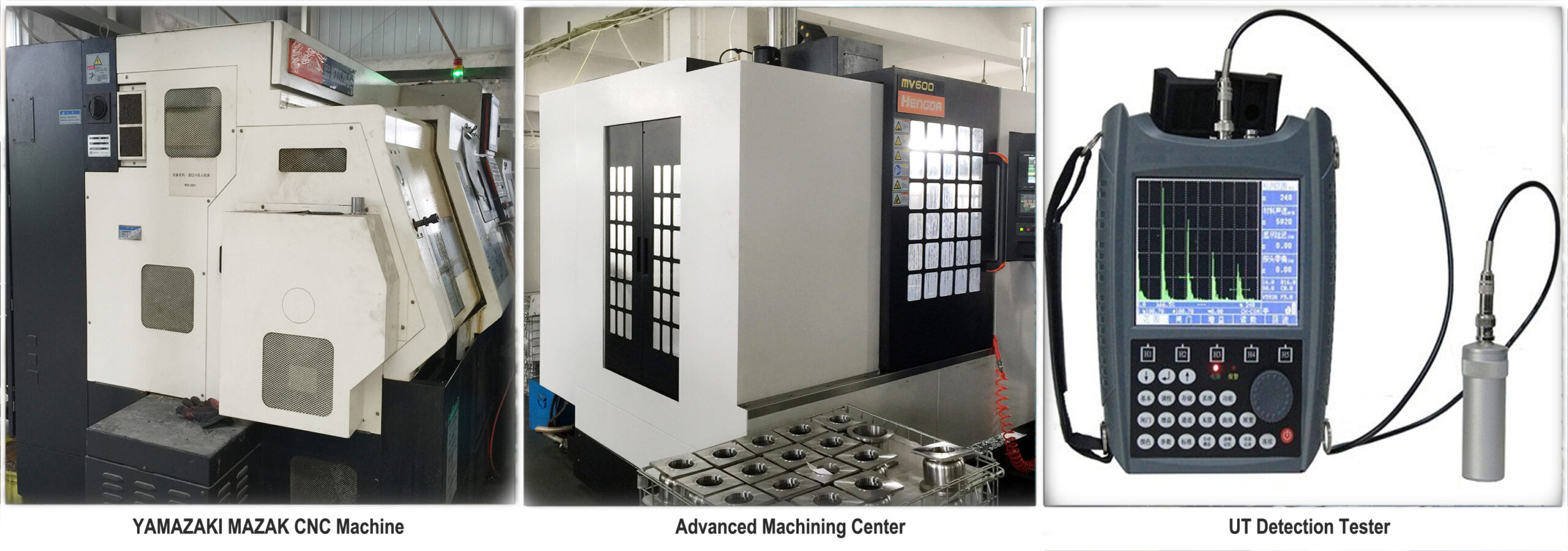

We have famous brand YAMAZAKI MAZAK CNC lathe machines imported from Japan and the most advanced milling machines. We perform UT inspection to ensure welding quality. We perform 100% appearance and dimension inspection on production line.

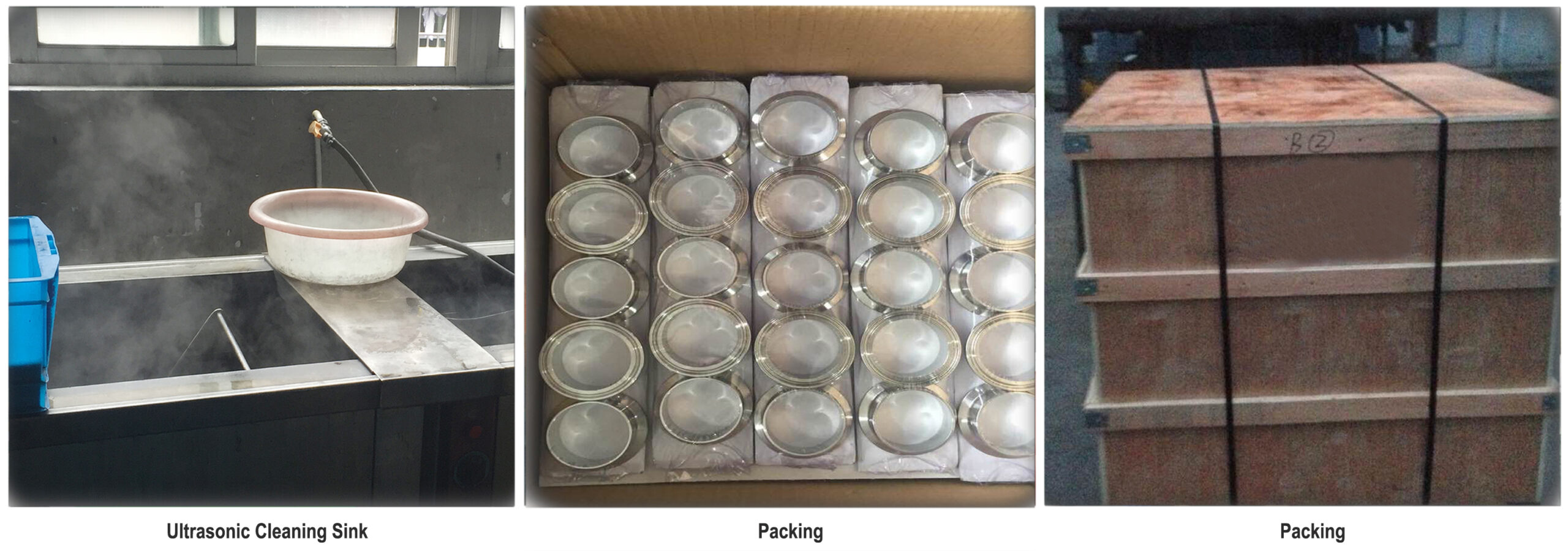

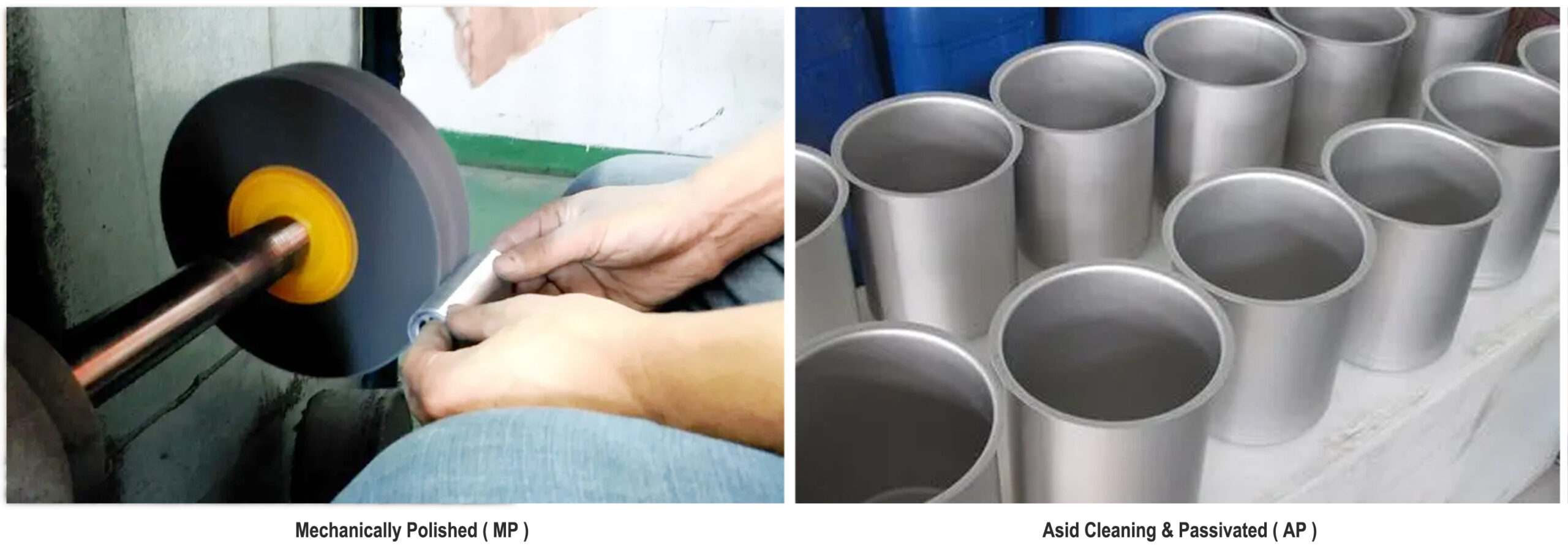

We offer the following surface polishing processes: mechanically polishing(MP) for surface brightness, acid cleaning & passivation (AP) for anti-corrosion performance, electrolysis polish (EP) to improve surface smoothness, Bright Annealing (BA) for eliminating stress to improve stainless steel toughness.

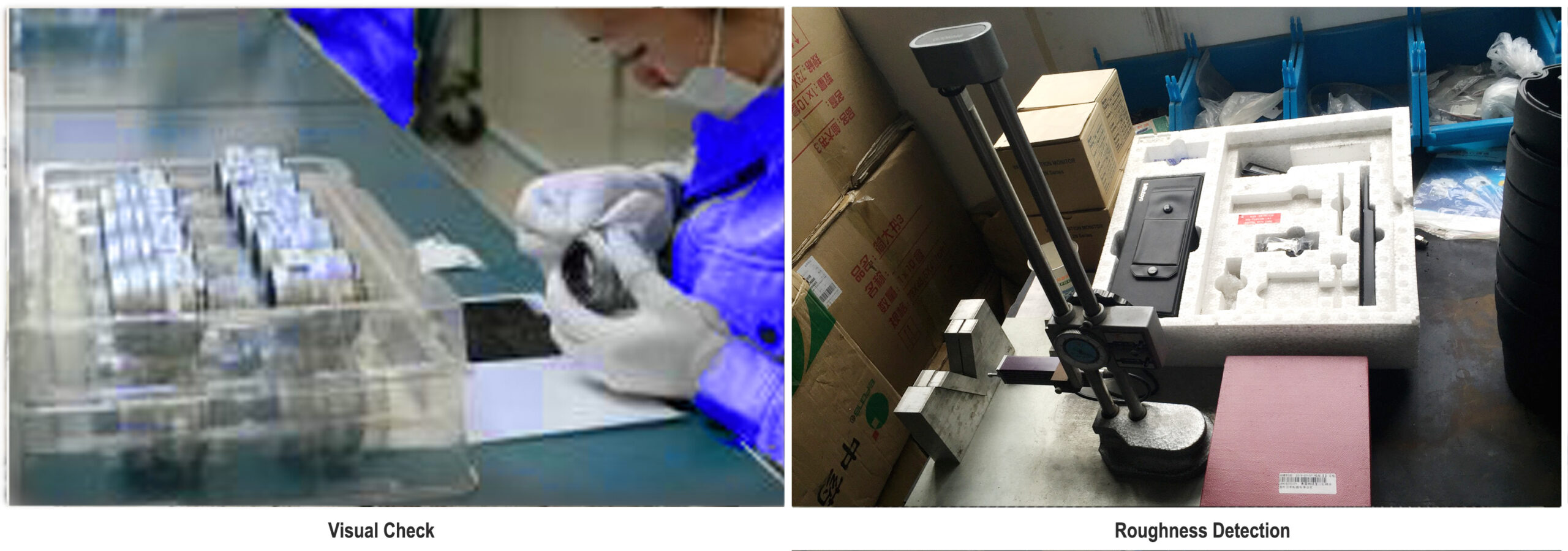

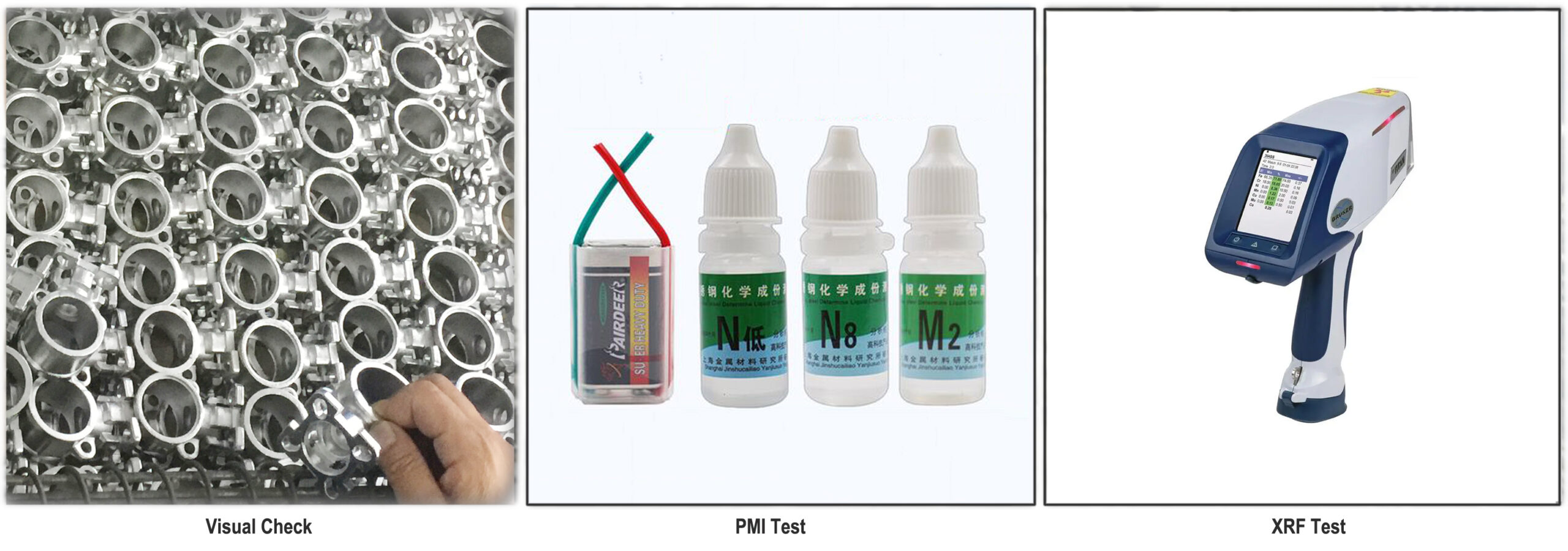

Visual check on the stainless steel surface, see if there is any scratches or not.

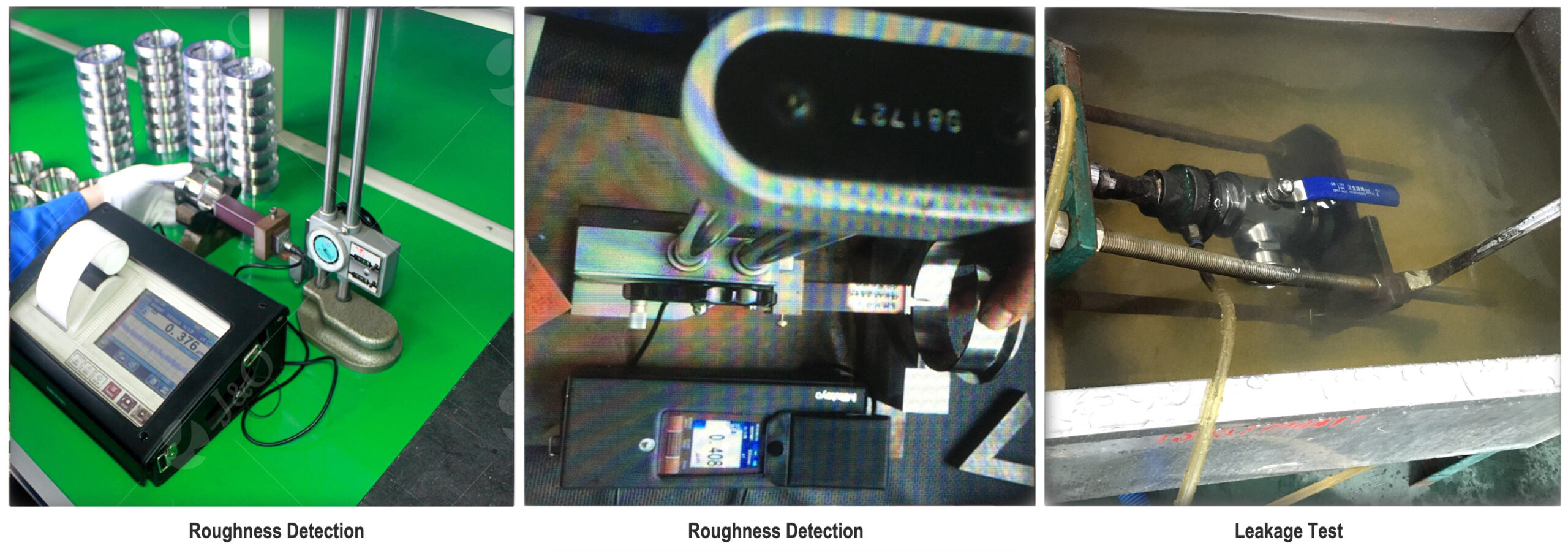

Roughness detection to ensure the surface is polished up to quality standard.