Raw Material:

Raw Material:

| Main parts: | One solenoid valve, two position sensors, on PCB, and enclosure |

| Communication type: | AS-i main line communication, or electronic communication |

| Input signal: | AC 220V, or DC 24V; 3 Watt |

| Working principle: | Communication between valves and control panel by receiving and sending signals with its monitoring and order devices. |

| Air supply pressure: | 4 bar ~ 8 bar |

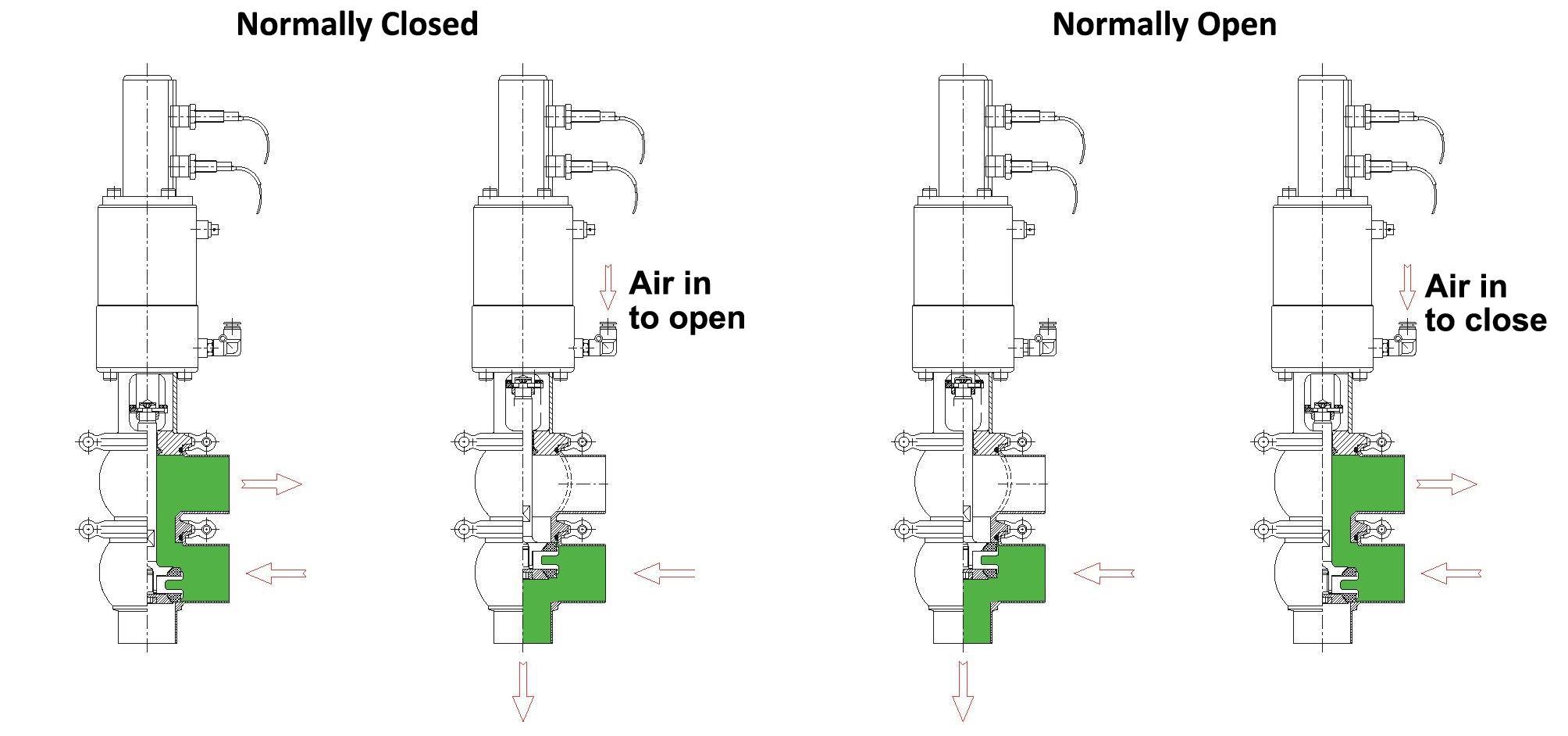

| Operation principle: | Double acting ( air / air ), or single acting ( air / spring ) |

| Operation mode: | Normally open ( NO ), or Normally closed ( NC ) |

Specification Details:

Specification Details:

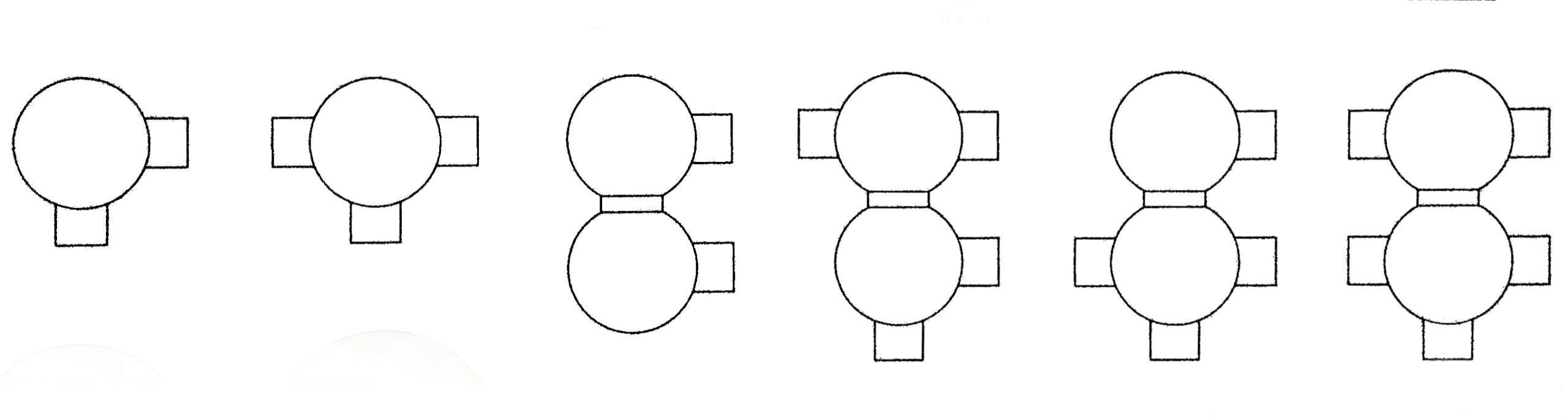

| Size: | DN25~100, 3/4”, 1”, 1 1/4”, 1 1/2”, 2”, 3”, 4” |

| Temperature: | -10~+100℃ |

| Fluid Pressure: | 0~10 bar |

| Connection End: | Clamp, weld, thread, and so on |

Product Show:

Product Show: