Operating Principle:

The sanitary check valve opens when fluid pressure exceeds the pressure from the pump sprin. When fluid pressure reduces back to the same level of pump spring, the sanitary check valve closes. Bigger pressure gap also could make the valve close.

Operating Principle:

The sanitary check valve opens when fluid pressure exceeds the pressure from the pump sprin. When fluid pressure reduces back to the same level of pump spring, the sanitary check valve closes. Bigger pressure gap also could make the valve close.

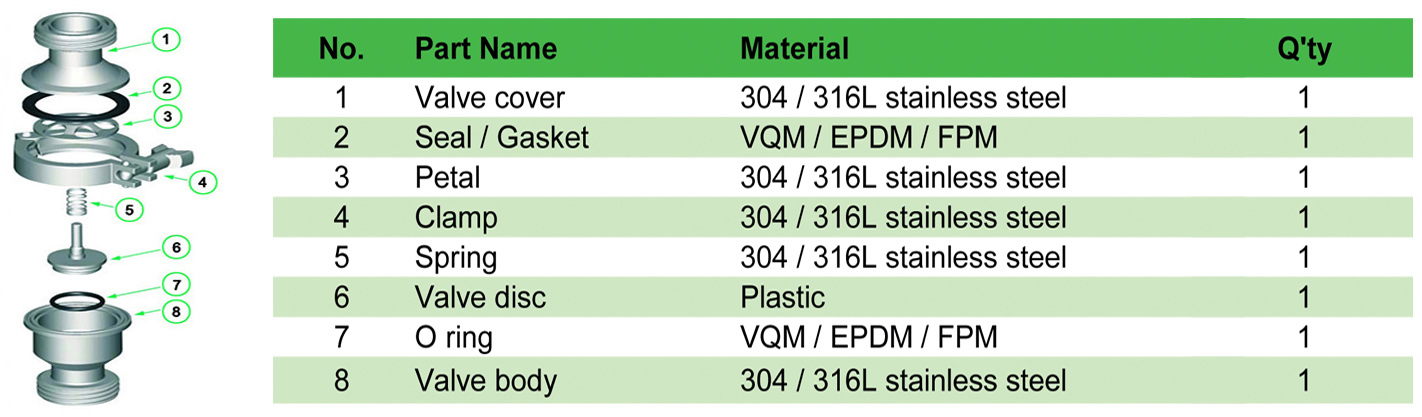

Main Parts:

Main Parts:

Specifications:

Specifications:

| Size: | 1/2″ – 4″ or DN15-DN100 |

| Thickness: | 1.5mm – 2mm |

| Material: | 304 or 316L stainless steel |

| Seal Material: | EPDM, FPM (Viton), NBR or PTFE |

| Standard: | 3A, ASME BPE, DIN11850, DIN11866, ISO1127, ISO2037 |

| Connection End: | Weld, clamp, thread, union, flange |

| Surface Finish: | Ra≤0.8μm |

| Working Temperature: | -10°C to +120°C ( EPDM ) |

| Max Pressure: | 10 Bar |

| Opening Pressure: | 0.3 Bar ( DN25 ), 0.2 Bar ( DN32/40 ), 0.1 Bar ( DN-50/100 ) |