Configuration:

Configuration:

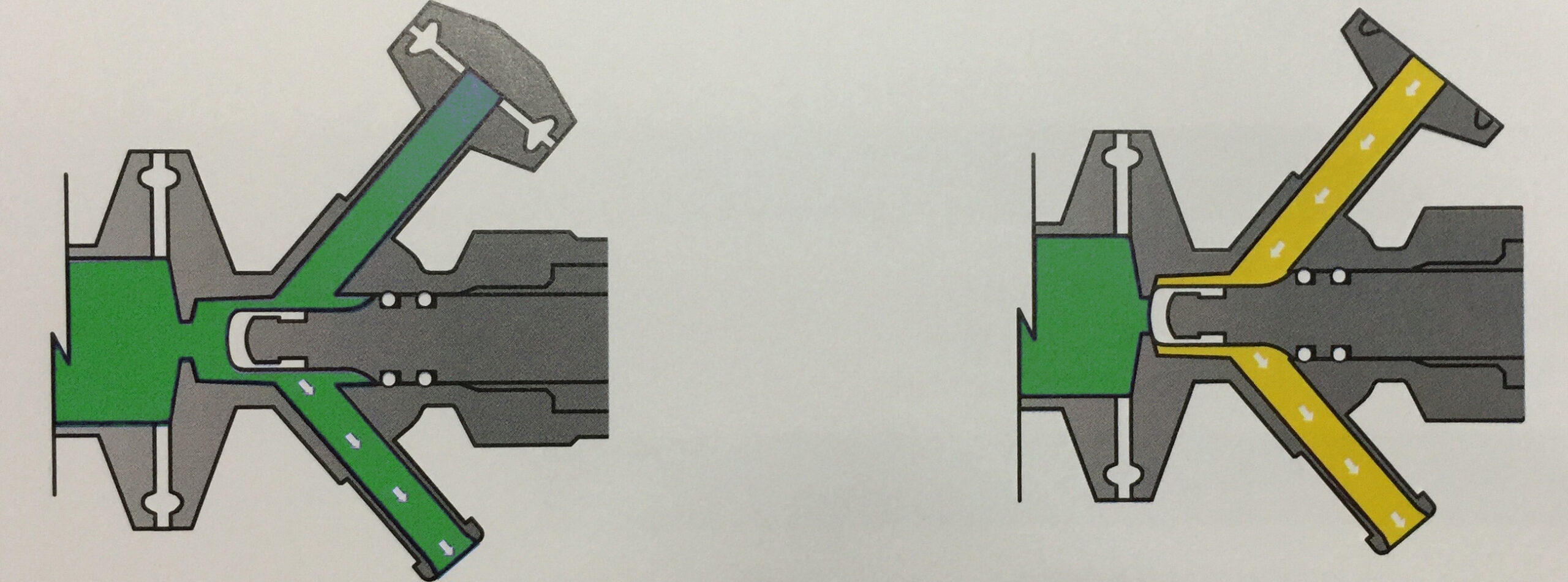

Working Principle:

The aseptic sampling / sample valve is designed for sterilization before and after sampling.

Working Principle:

The aseptic sampling / sample valve is designed for sterilization before and after sampling.

| Sterilization process before sampling | 1. The steam or sterilization medium is fed into one of sampling port to sterilize valve chamber 2. Another port discharges the sterilization medium |

| Sampling process | 1. Rotate the handle or lift the joystick to open the sample valve 2. The central shaft opens 3. Sampling 4. Close the valve |

| Sterilization process after sampling | 1. Inlet clean water to clean the valve chamber 2. Inject sterilization medium for sterilization |

Technical Specification:

Technical Specification:

| Trademark | WLM |

| Driven Mode | Manual or Pneumatic |

| Size | 1/4”, 3/8”, 1/2”, 3/4”, 1” |

| Valve Opening Pressure | Max. 6 bar |

| Valve Closing Pressure | Max. 12 bar (sealing head); Max. 15 bar); Max. 15 bar (stainless steel valve body) |

| Working Temperature | -20 ~ +120℃(EPDM seal) / 130℃(PTFE seal) |

| Sterilization Temperature | 150℃(Max. 20 minutes), dry steam |

| Surface Finishing | Inside surface R<0.8μm; outside surface R<1.6μm |