Specification Details:

Specification Details:

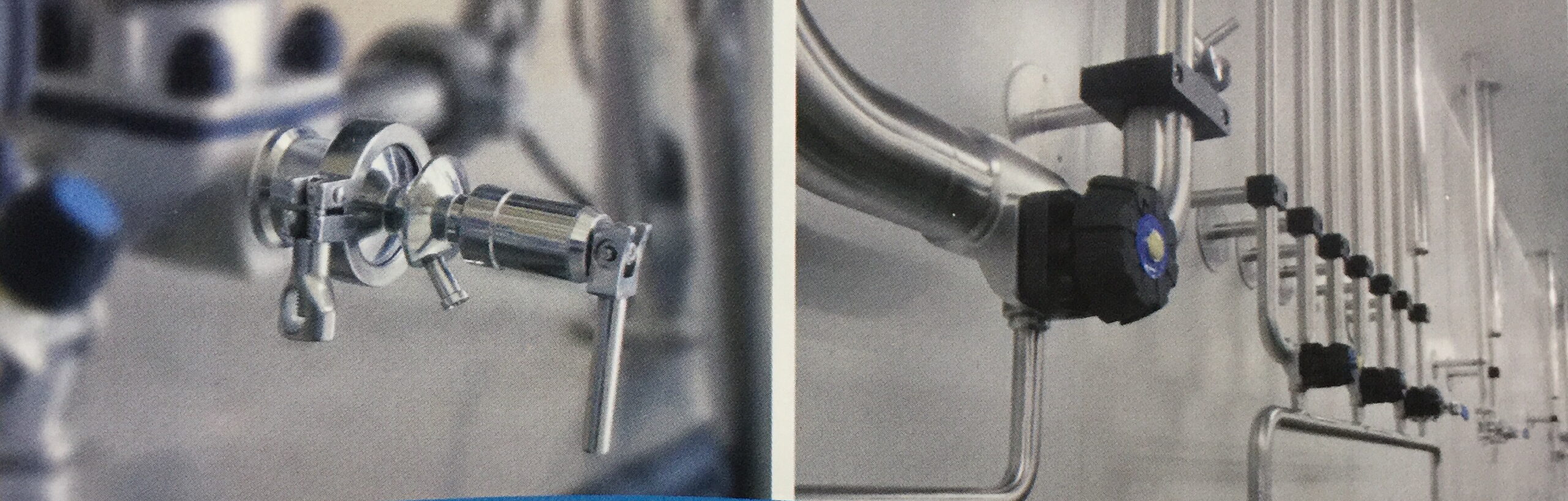

| Drive Mode | Manual lift handle and pneumatic actuator |

| Working Pressure | 0 ~ 8bar |

| Nominal Pressure | 16 bar PN |

| Size | 1/4”, 3/8”, 1/2”, 3/4”, 1” |

| Valve Body Material | SS304 or SS316L |

| Sealing Material | PTFE, VMQ, EPDM |

| Working Temperature | -20 ~ +120℃(EPDM seal) / 130℃(PTFE seal) |

| Connection End | Butt weld, clamp or male female thread |

| Body Structure | Single branch port; double branch ports(for sterilization) |

| Surface Treatment | Mechanical polishing, electrolytic polishing |

| Surface Finish | Ra<1.6μm |

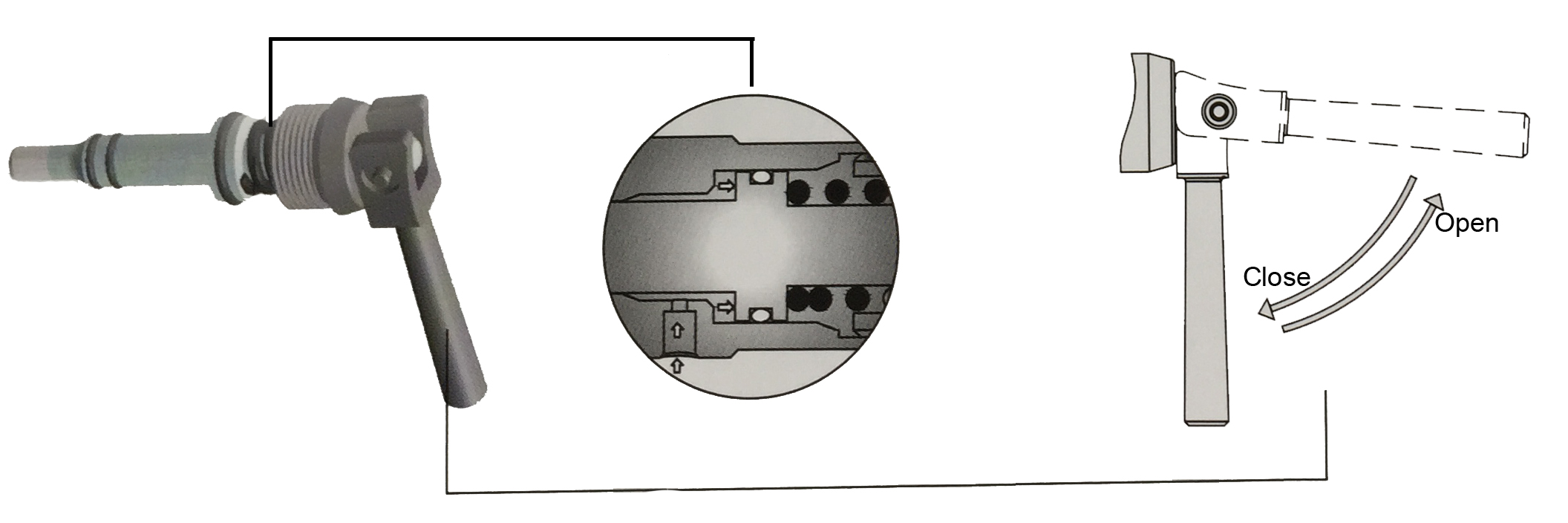

| Part Name | Material | Temp. & Pressure | Features |

| Sample inlet seal | PTFE | 190 ℃ / 8 bar | Hygienic, high pressure resistant, strong anti-corrosion ability, long lifetime |

| Sample inlet seal | EPDM | 130 ℃ / 6 bar | Hygienic, excellent sealing performance, strong anti-corrosion ability |

| O-Ring | MVQ | 190 ℃ / 8 bar | Hygienic, high pressure resistant, strong anti-corrosion ability, long lifetime |

| O-Ring | EPDM | 130 ℃ / 6 bar | Hygienic, excellent sealing performance, strong anti-corrosion ability |

Valve Body Configuration:

Valve Body Configuration:

| Valve Body | Figure | Sample Flow Diagram | Function |

| Single branch port hose end |  |

|

Quick sample collection |

| Single branch port clamp end |  |

|

Quick sample collection |

| Double branch ports hose end |  |

|

Sample collection & sterilization |

| Double branch ports clamp end |  |

|

Sample collection & sterilization |

| Double branch ports hose / clamp end |  |

|

Sample collection & sterilization |

| Connection Ends | Figure | Characteristics |

| Tri Clamp |  |

Hygienic, safe, easy installation & disassembly |

| Butt Weld |  |

Hygienic, safe, reliable |

| Male / Female Thread |  |

Easy installation & disassembly, space saving |